μMLA

MLA150

MLA300

桌上型无掩模光刻机

无掩模光刻系统

专业自动化无掩模光刻系统

CONFIGURABLE AND COMPACT TABLETOP MASKLESS ALIGNER WITH RASTER SCAN AND VECTOR EXPOSURE MODULES

无掩模对准器,可配置光栅扫描和矢量曝光模块

THE ADVANCED MASKLESS ALIGNER

用于研发和小批量生产的先进激光直写系统

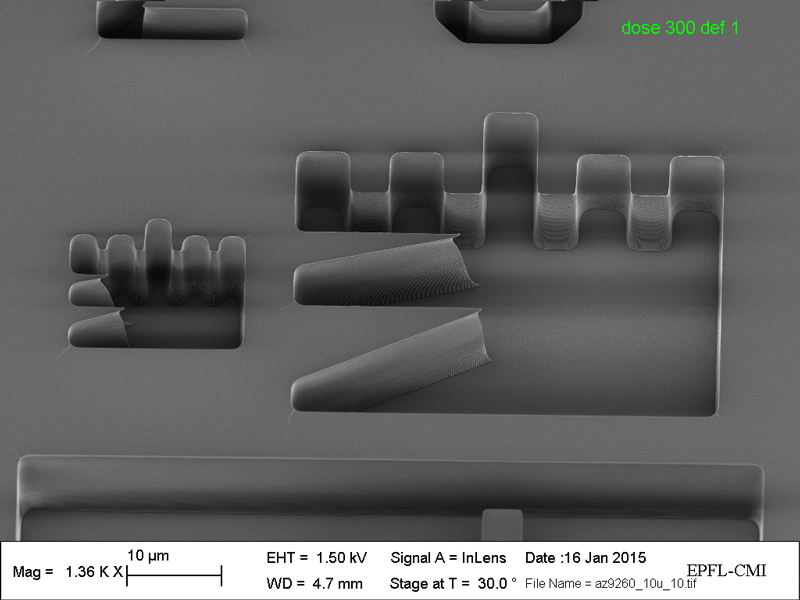

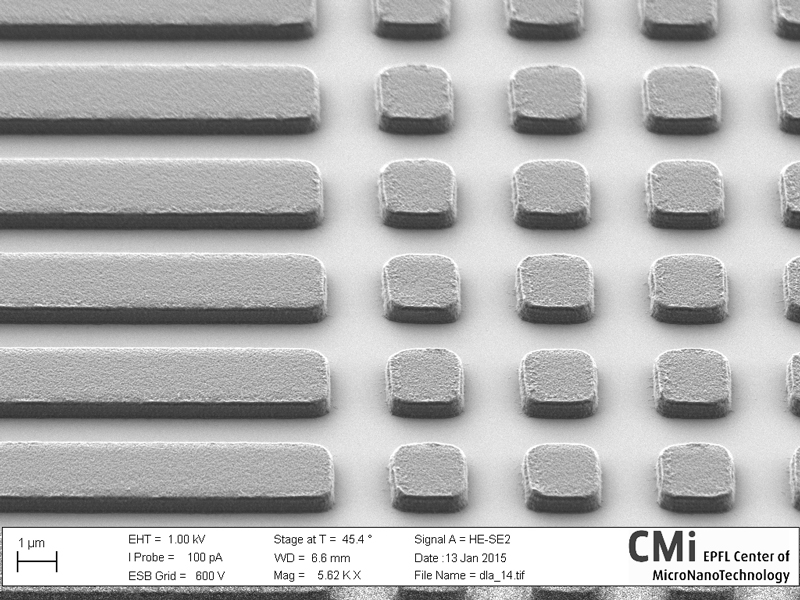

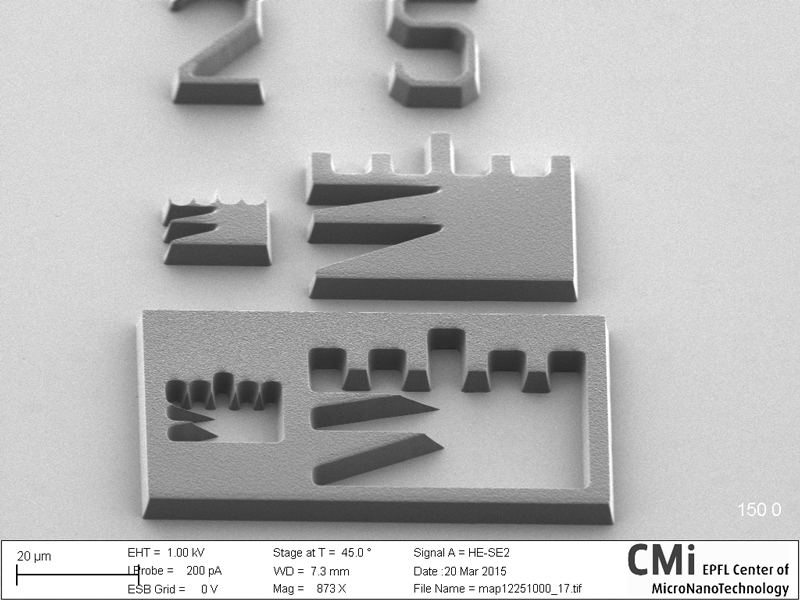

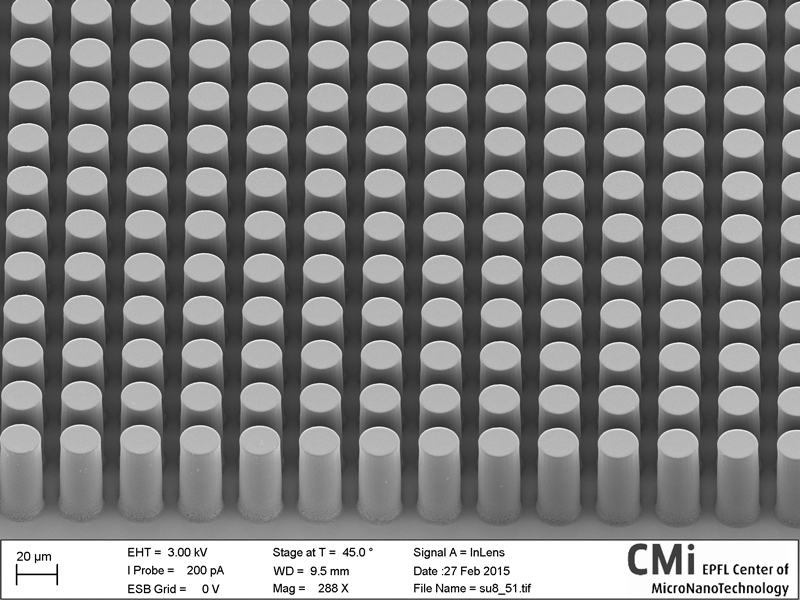

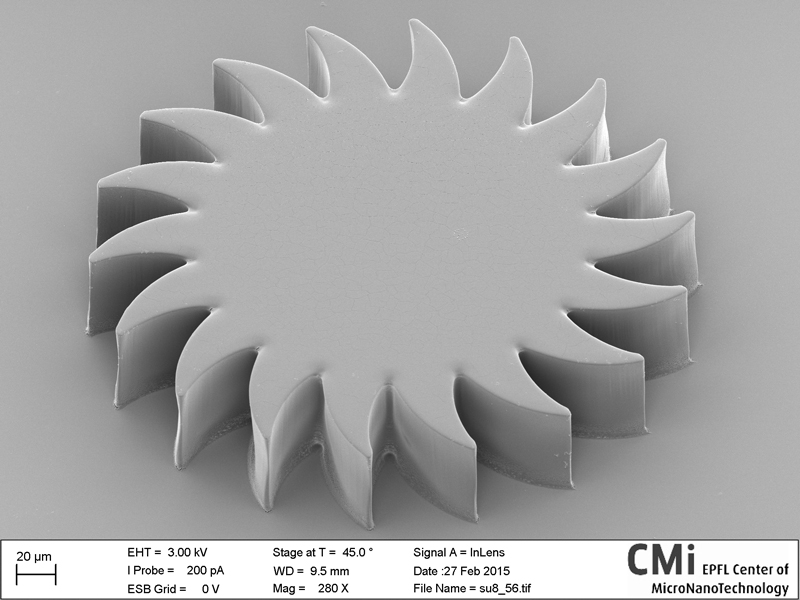

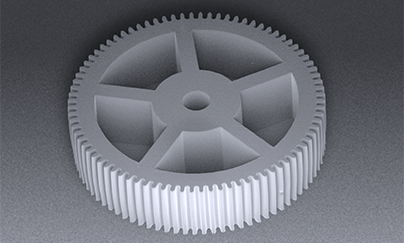

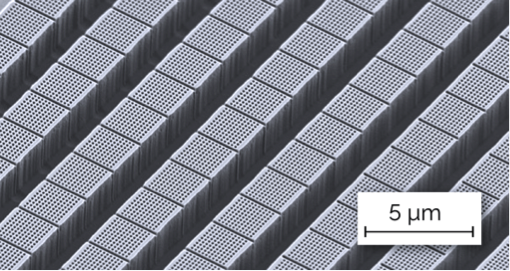

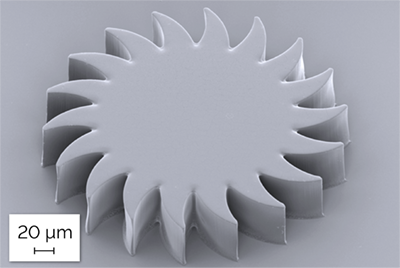

OPTIMIZED FOR INDUSTRIAL MANUFACTURING, ENSURING HIGH THROUGHPUT AND SEAMLESS PRODUCTION LINE INTEGRATION

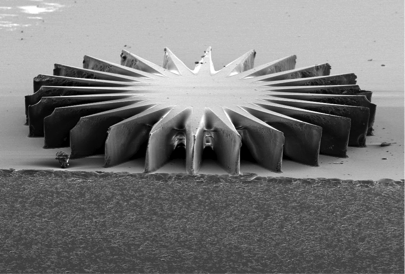

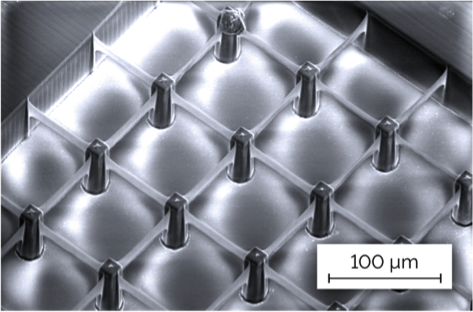

µMLA 是一款基于稳健的 µPG 平台打造的先进桌上型无掩模光刻系统,该平台是全球最畅销的台式无掩模解决方案。 它非常适合作为研发和快速原型制作的入门级工具,能够在多种应用中实现高精度微结构加工,包括微流控(如细胞分选器件、芯片实验室)、 小规模掩模制作、微光学与微透镜阵列、传感器制造、MEMS,以及二维材料和扇出电极(fan-out electrodes)的图案化。

µMLA 通过两种不同的曝光模式提供灵活性:

-

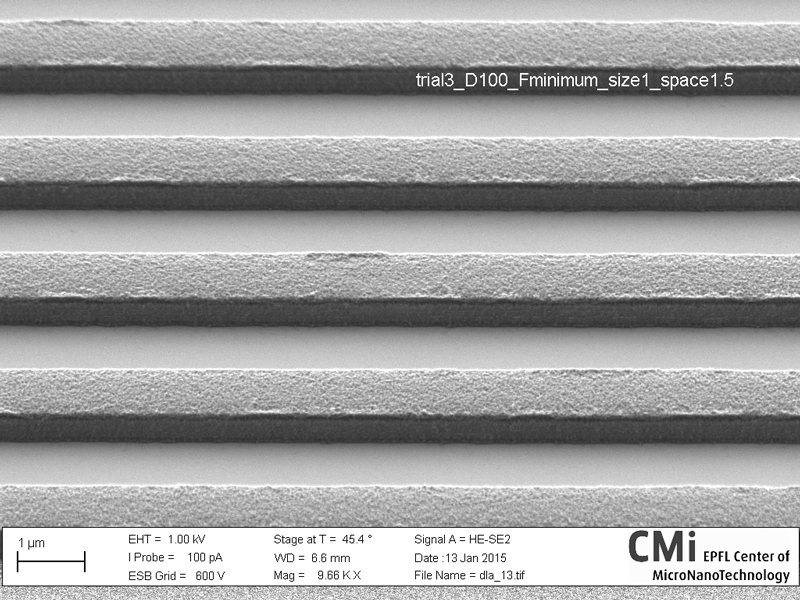

光栅扫描模式(标准):

确保快速曝光和出色的图像质量,无论结构尺寸和图案密度如何,都能保持一致的写入时间。 -

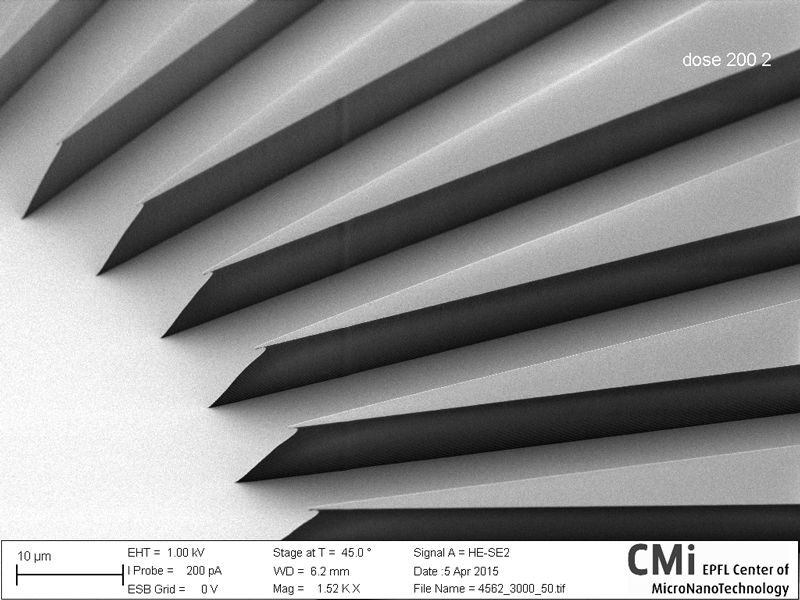

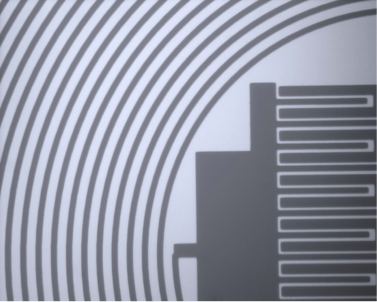

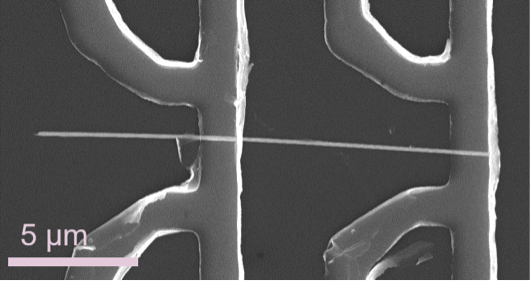

矢量扫描模式(选配):

专为连续、平滑的曲线而设计,是波导等结构的理想选择,兼具速度和精度。

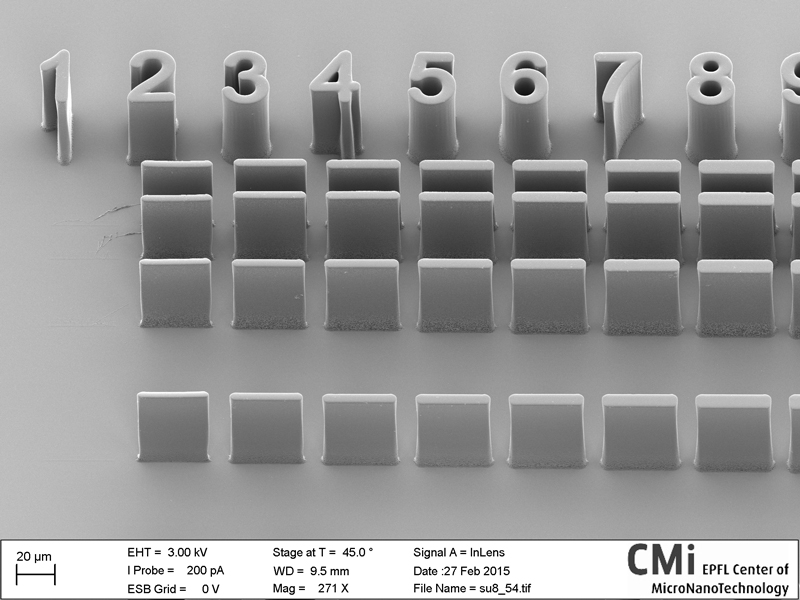

三种光学配置可在分辨率和吞吐量之间实现可定制的平衡,切换方便,可针对特定应用进行优化 其他功能包括:

-

绘制模式:

对现有图案和电极触点进行实时调整,适用于纳米线或二维材料。 -

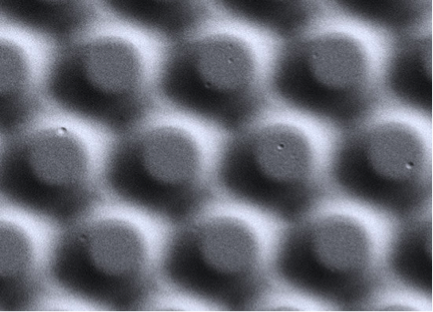

灰度模式:

支持 2.5D 结构,适用于复杂的微光学器件。

µMLA 桌面式设计,可放置于标准工作台上,提供一套全面的功能,适用各种高质量光刻应用。

請联系我们,进一步了解µMLA 及其如何满足您的研发需求;从CAD到曝光只需几分钟,而非数周。

您是否因掩模版成本高、交货期长而感到推进迟缓?您是否希望不需要对传统掩模对准器进行冗长的培训就能立即执行设计?

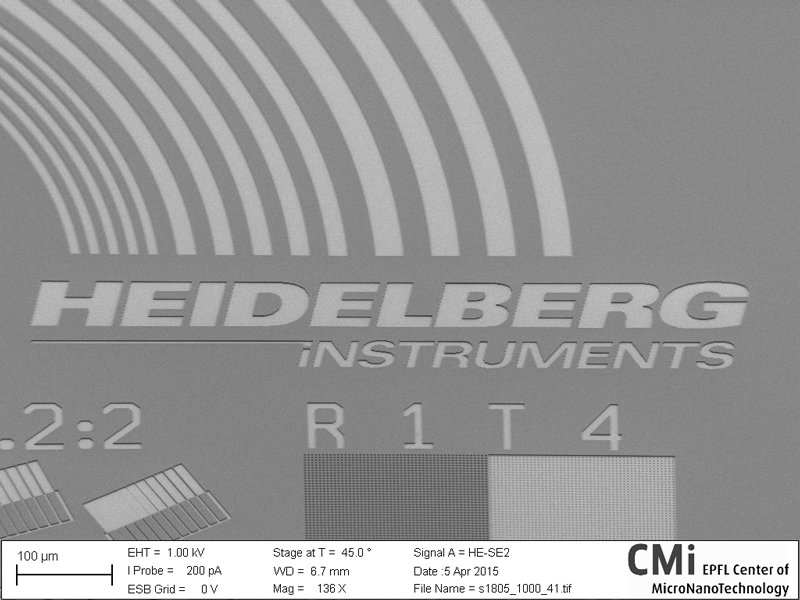

探索MLA 150 和数字光刻世界

这种现代化的无掩模对准器采用快速、灵活、易于使用的解决方案取代传统技术,具有最高的性能。通过使用数字微镜器件(DMD)作为动态掩模,MLA 150 克服了物理光掩模的缺点。从数字设计到完美图案化的基底只需几分钟,使您的用户能够加速量子器件、微机电系统、微光学和生命科学等领域的研究。

为什么MLA 150 是实验室的理想选择?

MLA 150从设计之初就致力于解决学术和工业研发机构面临的核心挑战,它直接解决了光掩模前置时间长、经常性成本高以及传统系统曲线陡峭等问题。

专为多用户设施而打造

减少培训开销,并最大限度地延长工具正常运行时间。MLA 150 非常直观,新用户只需不到一个小时就能完全胜任独立工作。其操作软件和简化的工作流程非常适合共享实验室环境,这也是MLA 150 成为领先全球净房必备工具的原因所在。

先进科研及更多应用的卓越灵活性

您的工作独一无二,您的光刻设备亦当如此。无论是推进前沿研究、通过快速原型加速创新,还是进行高质量的小批量生产,MLA 150 都能适应您的需求,而不是让您适应设备。

-

广泛兼容各类光刻胶::

同时安装一个或两个不同的激光波长(375 nm 和/或 405 nm),无需更改硬件即可曝光所有宽带、g、h 和 i 线光刻胶。 -

轻松应对复杂基材:

专用真空吸盘可让您轻松处理难以处理的样品,包括小至 3×3 mm²的小基片、薄箔和翘曲硅片。 -

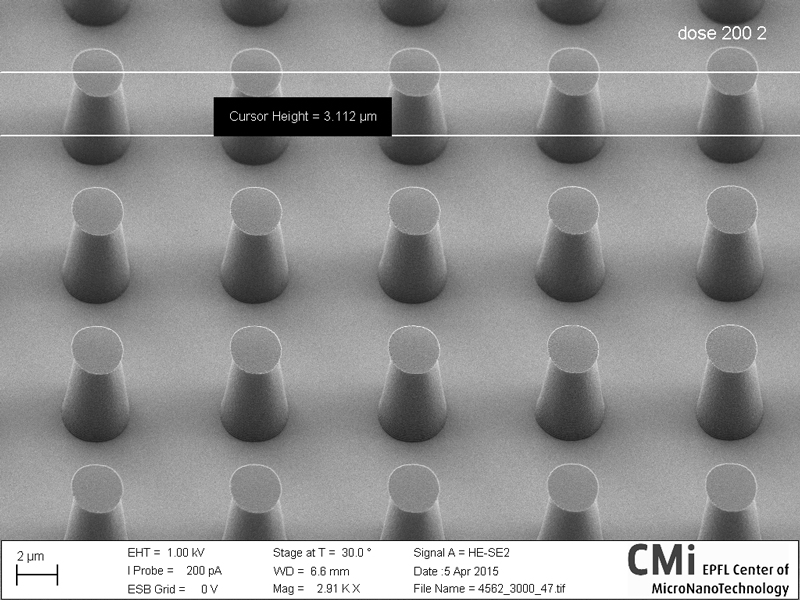

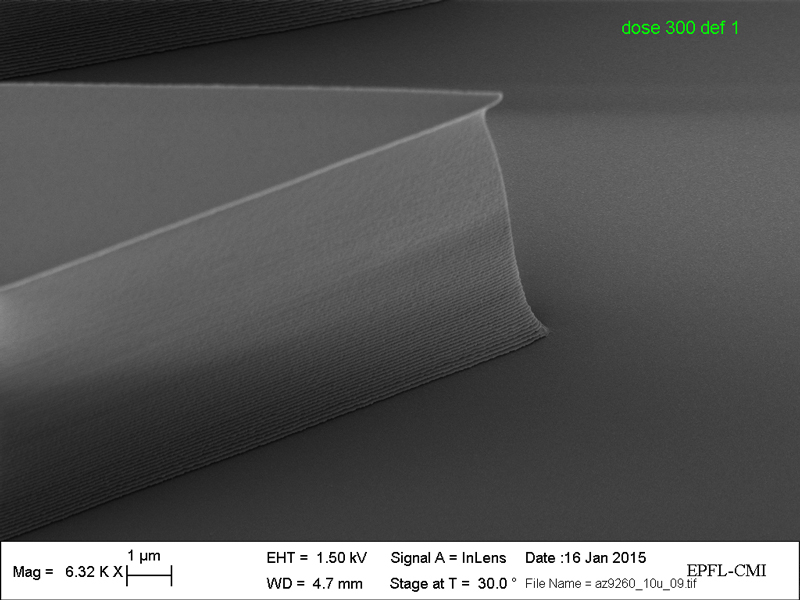

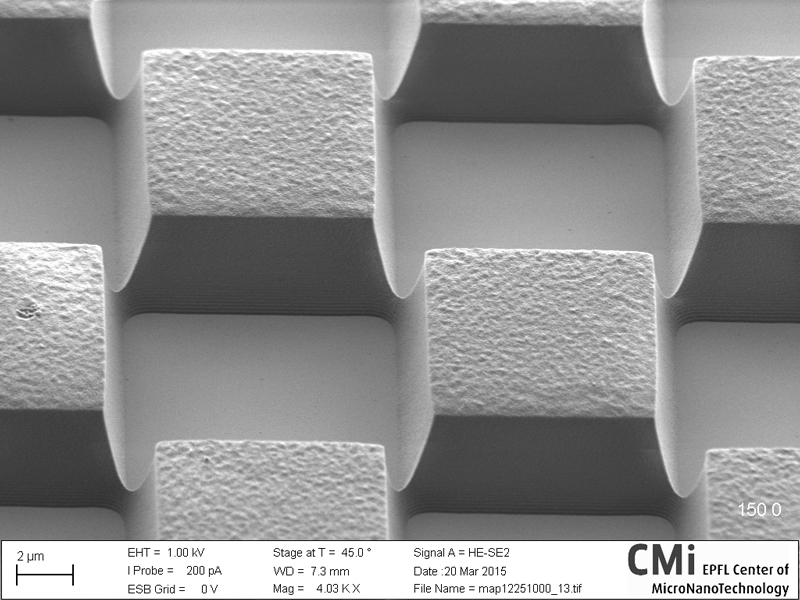

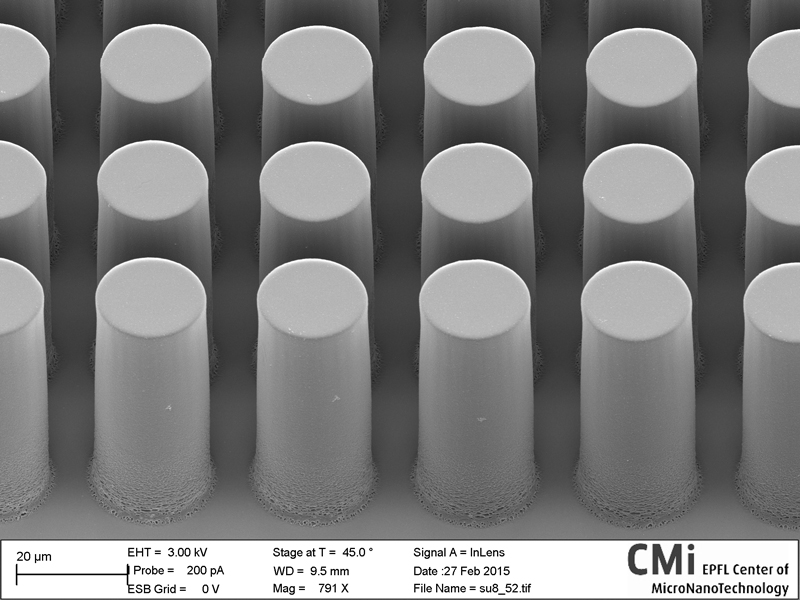

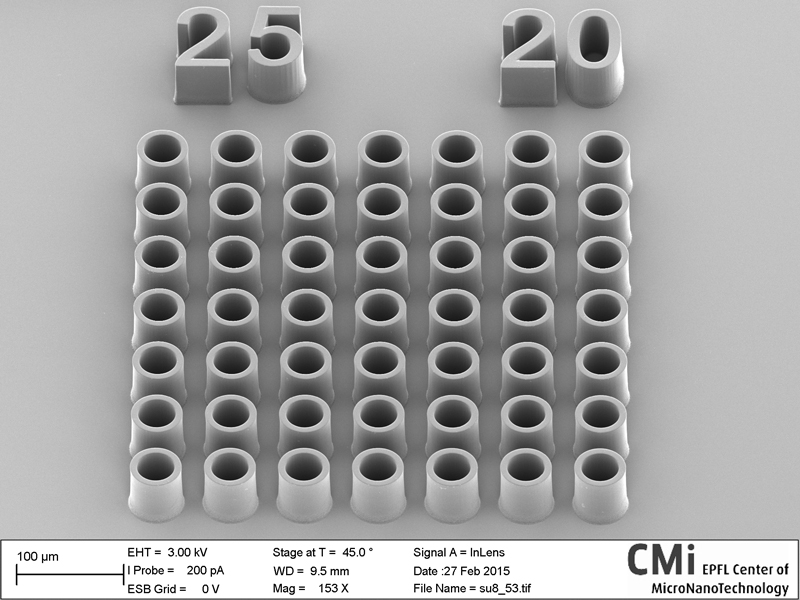

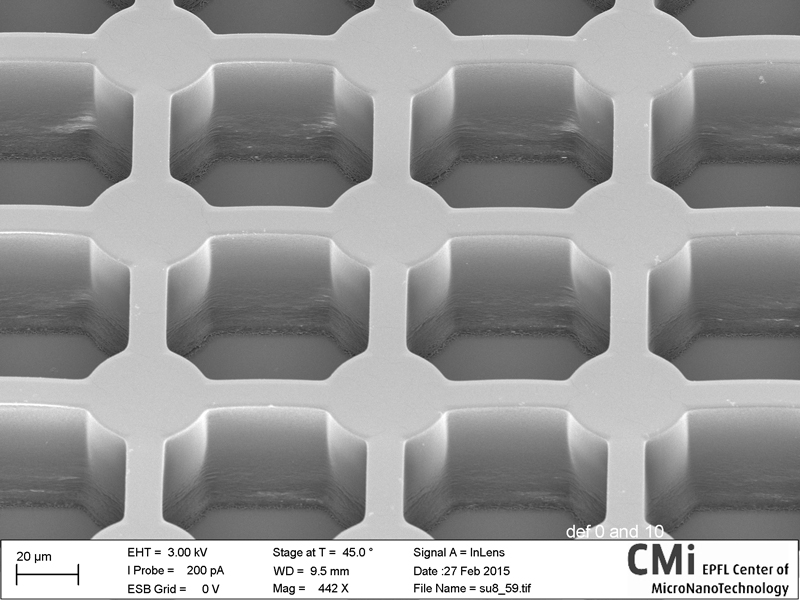

创建 2.5D 高深宽比结构:

使用灰度光刻模式可制造复杂的 2.5D 微结构,或使用高深宽比模式在厚光刻胶中形成陡直的侧壁图形,非常适用于 MEMS 和微流体应用。 -

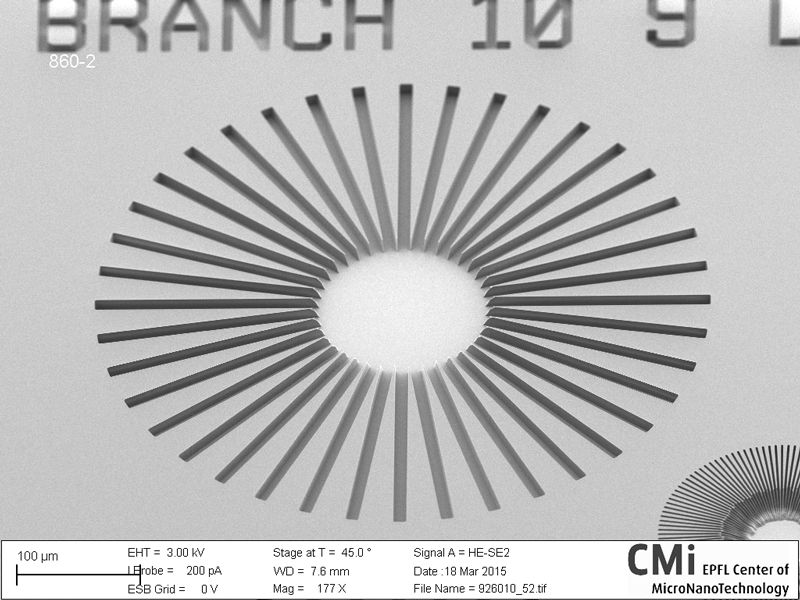

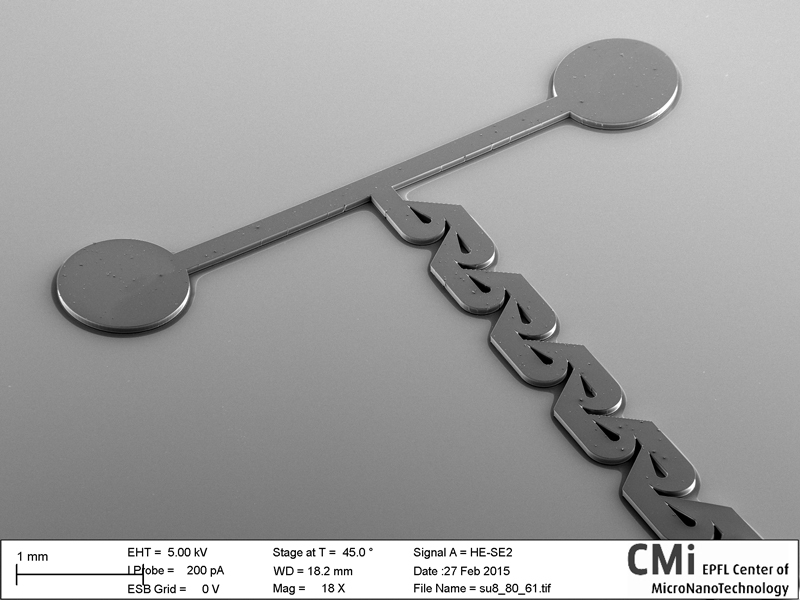

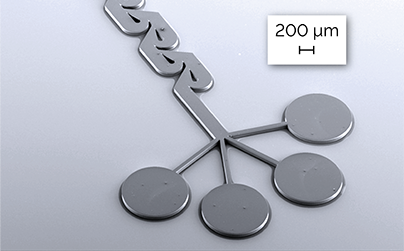

交互式 绘制模式:

在样品的实时摄像图像上直接绘制和曝光图案,特别适用快速制作原型或在石墨烯薄片、纳米线等特殊结构上精确定位电极。

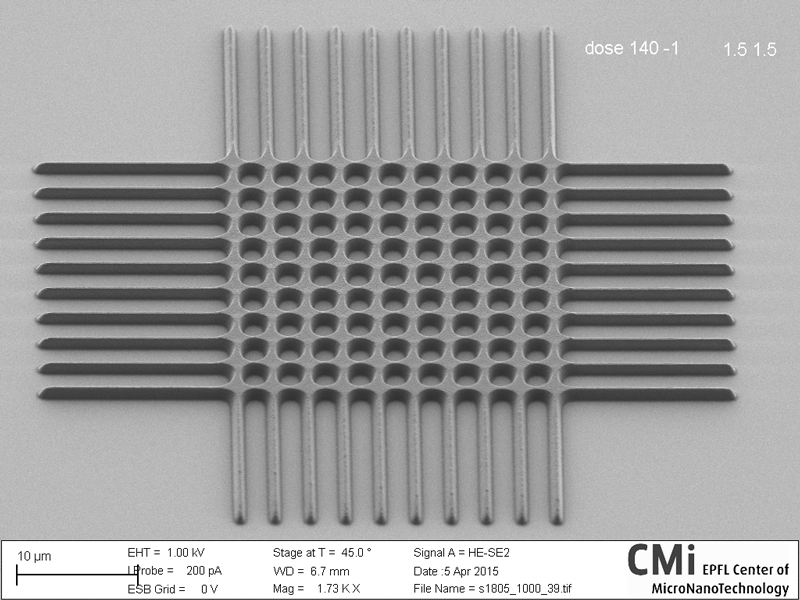

高产速、高精度、不妥协

用户友善并不等同低性能。MLA 150以卓越的速度和精度,突破制造的极限。

-

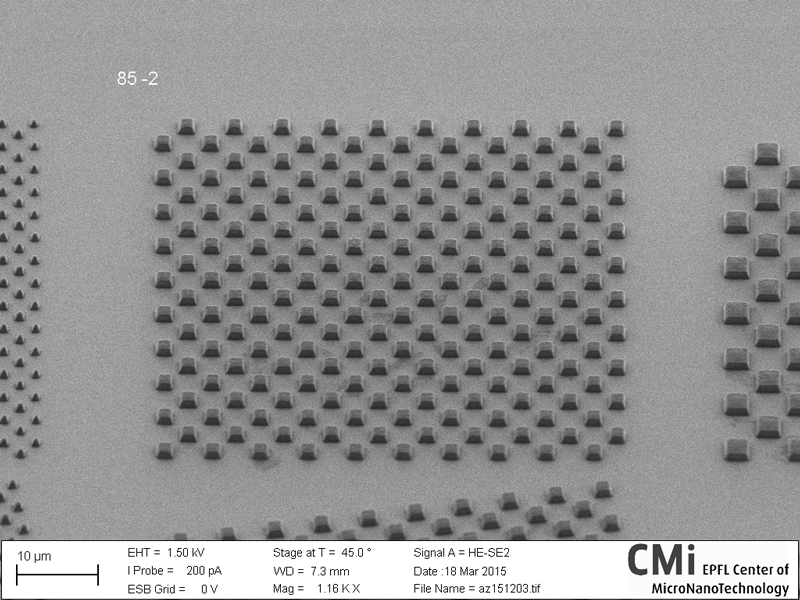

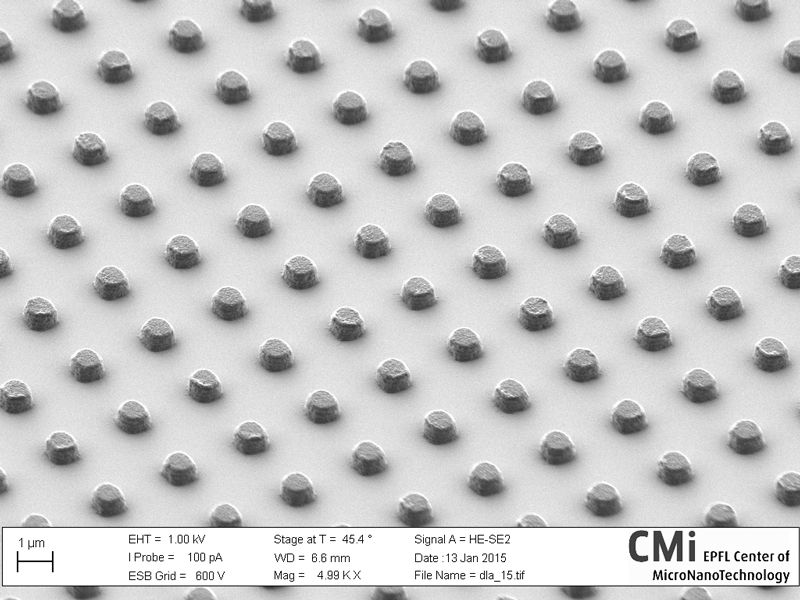

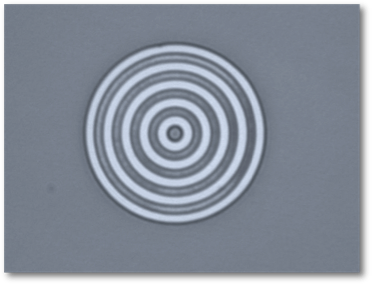

亚微米级分辨率:

实现最小0.45微米特征尺寸,轻松制备复杂高分辨率器件。 -

卓越产能表现:

单次曝光150毫米硅片仅需不到16分钟。 -

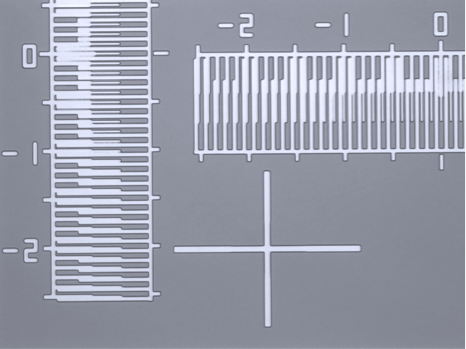

先进的自动对准系統:

250纳米级对准精度,数字化补偿偏移、旋转、缩放及剪切误差 —物理掩模无法实现的精准调整。 -

完美对焦:

动态自动对焦系统确保图形清晰均匀,轻松应对图案化、翘曲及脆弱基材。 -

极致环境稳定性:

集成温控层流环境舱(±0.1°C精密控温),有效抑制热膨胀效应,确保结果稳定可重复。

大幅降低运营成本

彻底消除光刻工艺中最大且持续的成本——掩模版。

MLA 150无需光罩采购,省去数周交期等待,同时免去清洗、存储流程,规避高额破损风险。结合10-20年超长激光寿命及简易维护,MLA 150实现行业领先的综合持有成本。

主要应用

从基础物理学到应用生物科学,MLA 150 都是值得信赖的工具:

-

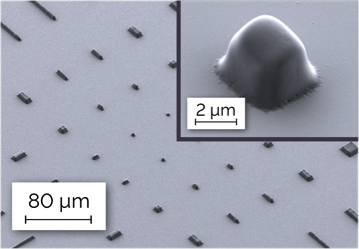

纳米加工:

量子设备、二维材料、半导体纳米线 -

MEMS 和 MOEMS:

传感器、致动器、微光元件、微流体 -

材料科学:

新型材料的图案化加工 -

生命科學:

芯片实验室、生物传感器

携手全球数百家顶尖科研机构

全球数百所一流大学和研究中心已选择MLA 150替代传统光刻机。

立即联系我们,了解如何为您的用户赋能,实现实验室技术升级。

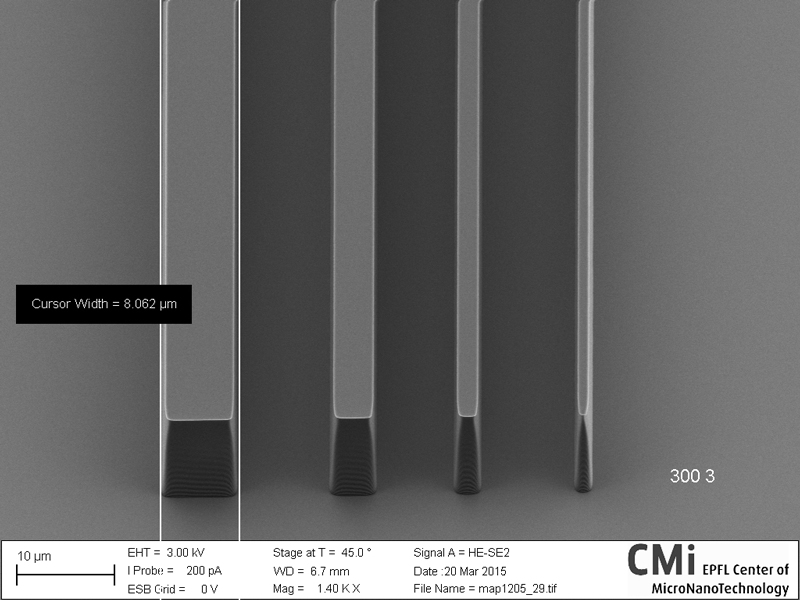

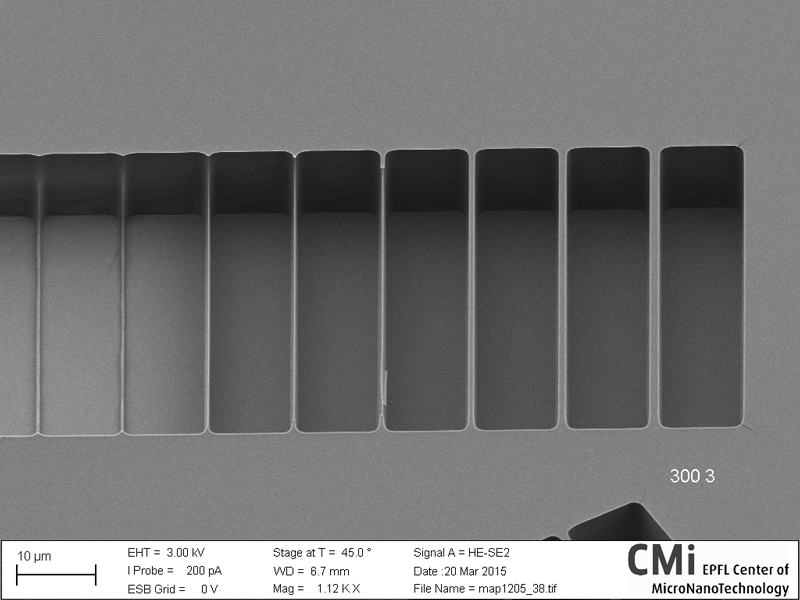

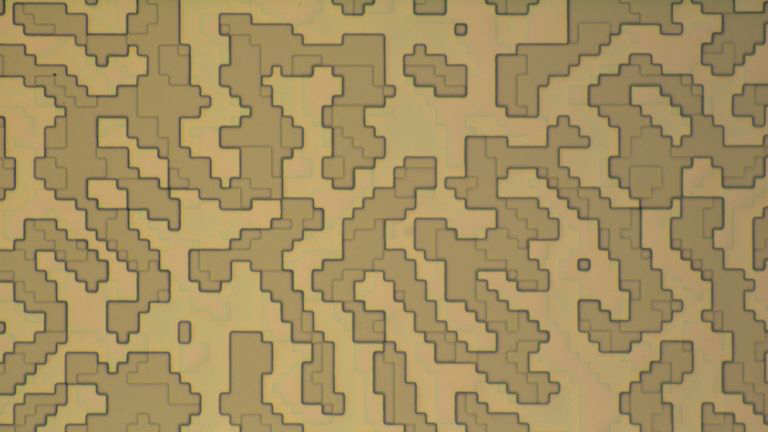

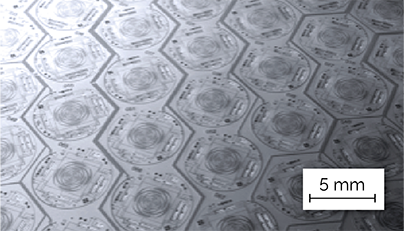

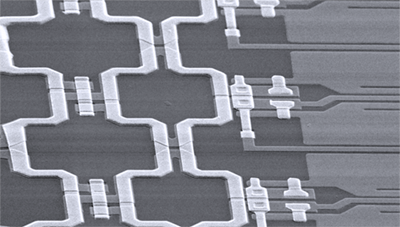

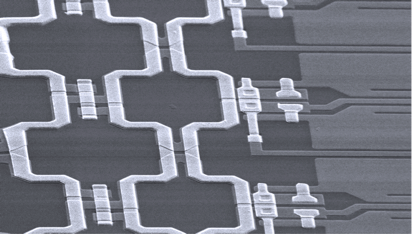

无掩模对准器MLA 300 专为大批量生产而设计,在工业光刻领域具有无与伦比的灵活性和精确性。 它支持最大 300 x 300 mm的芯片,能动态适应表面变化,无需昂贵且耗时的掩模生产。通过用直接数据曝光取代传统掩模,MLA 300 可为先进封装、 传感器校准和微机电系统制造等复杂光刻挑战提供创新解决方案。其高通量、1.5 μm 分辨率、简化的工作流程以及与制造执行系统 (MES) 的无缝集成, 使其成为包括微流控设备和其他先进技术在内的各种应用的理想选择。

主要功能

-

高通量生产:

针对工业规模生产进行了优化,最小特征尺寸为 1.5 µm。对于更高产量需求,我们还提供最小特征尺寸为 3 µm 的高通量写入模式。 -

高精度:

该系统具有卓越的光学质量,确保在各种具有挑战性的基底上实现精确制图。 -

全自动化:

MLA 300 具有全自动化功能,包括可定制的装载选项、专为生产环境设计的高级软件以及与 MES 系统的集成。 -

获得专利的基板跟踪技术:

实时自动对焦可补偿基板翘曲或波纹,确保在所有表面上实现完美无瑕的图案化和均匀性。

应用

-

先进的封装:

可进行扇出型芯片封装,并补偿芯片偏移和芯片高度变化。 -

传感器和传感器集成电路:

专为高精度传感器制造设计,确保精确和可定制的图案化。 -

MEMS 和微流控器件:

非常适合 MEMS 和微流控应用中所需的复杂设计。 -

分立电子元件:

支持高精度、高适应性的各种电子元件的生产。 -

集成电路和专用集成电路(ASIC):

针对高效生产模拟和数字集成电路以及专用集成电路进行了优化。 -

探针卡:

通过确保精确的图案化和对准,实现高精度探针卡生产,从而提高测试和检验效率。 -

电力电子:

针对陶瓷等基材进行了优化,可克服翘曲和厚度变化,提供稳定的质量。 -

OLED 显示屏:

高精度和高灵活性使MLA 300 成为 OLED 显示屏制造的理想选择。

工作流程和成本效益

-

无掩模光刻技术克服了传统掩模系统的局限性,为芯片图案校正、质量控制序列化以及传感器应用中的校准追踪提供了灵活的框架。

-

MLA 300 无需进行掩模版采购、验证和管理,从而简化了生产流程,直接从数据曝光设计,降低了时间和复杂性。

-

MLA 300 凭借其先进的功能提高了良率,特别是在热处理等具有挑战性的基板应用中。

-

实时自动对焦系统可补偿基板翘曲或波纹,即使在不平整的表面上也能确保完美的图案化。

-

该系统采用长寿命二极管激光器,在 24/7 全天候生产情况下估计可使用长达 10 年,而且系统极低的耗材需求,最大限度的降低运营成本。

-

模块化设计便于快速维护,最大限度减少了停机时间。

欲了解更多关于无掩模对准器MLA 300,以及它如何优化您的高通量微加工流程,请联系我们。

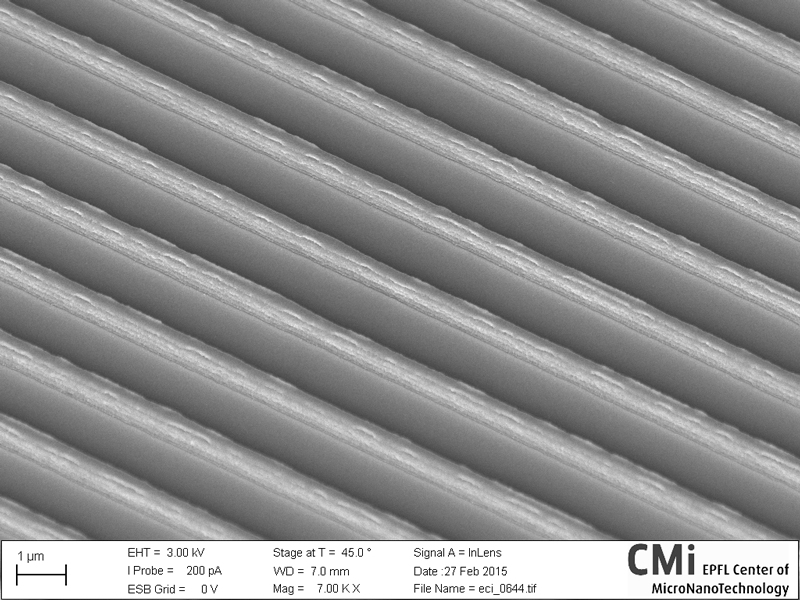

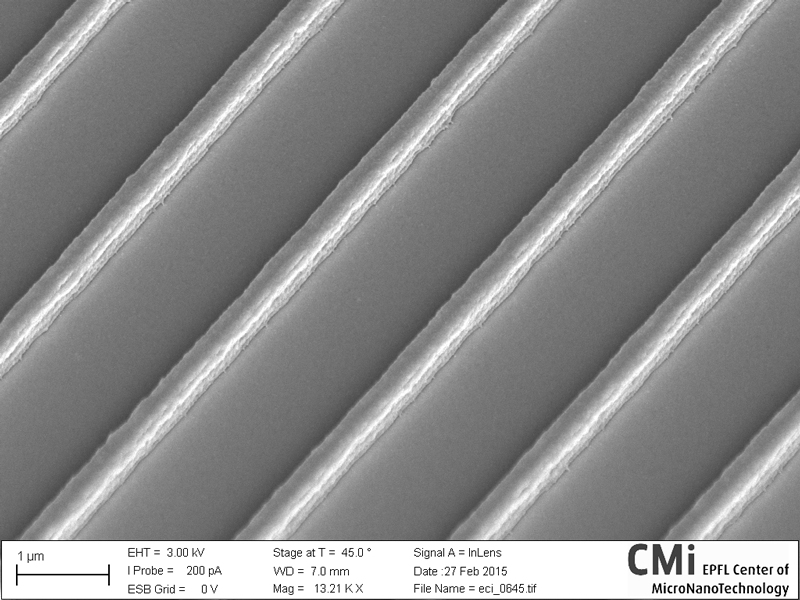

PRODUCT HIGHLIGHTS

Direct-write Lithography No mask-related costs, effort, or security risks Exposure Quality Edge roughness raster mode 100 nm; vector mode 30 nm; CD uniformity 200 nm Exposure Speed 4″ wafer in 90 minutes Grayscale Lithography With up to 256 gray levels, the grayscale exposure capability is part of the standard configuration Small Footprint 640 mm x 840 mm x 530 mm / 25″ x 33″ x 21″ – the smallest tabletop maskless lithography tool Flexible Configuration Choice of exposure wavelength; a choice of Raster and Vector Scan Modules Flexible Use Software enables easy switching for variable resolution and throughput speeds User-friendly Intuitive software and tool operation; easy handling of small samples Plug-and-play Setup Simplified plug-and-play installation reduces overall implementation time and saves costs

多用户实验室的理想之选

用户培训仅需不到1小时

快速准确的对准

250纳米正面/背面对准及误差补偿

卓越的工艺灵活性

双激光并行配置,全面覆盖各类光刻胶

多多种曝光模式可选,兼顾效率与精度

配备专用真空吸盘,轻松应对小型基板、薄膜及翘曲样品

低成本与易维护性

激光寿命长达 10-20 年

直写光刻技术

零掩模版成本,免维护,无安全风险

灰度光刻模式

轻松实现2.5D结构

曝光质量

边缘粗糙度60纳米、关键尺寸(CD)均匀性100纳米、自动聚焦补偿翘曲/波纹基板

最小特征尺寸

提供两种不同的写入模式,最小特征尺寸可达 0.45 μm

方便用户

专用软件与标准化工作流程,操作直观高效

曝光速度

405纳米激光波长下,150毫米硅片全程<16分钟

Direct-write Lithography No mask-related costs, effort, or security risks Flexibility Direct writing in industrial production allows per-die pattern corrections, e.g. to react to distortions or process variations and serialization Time-saving Shorter time from prototyping to production. Digital design management replaces conventional mask librarys Exposure Quality Optical compensation of scaling, rotation; patented substrate tracking technology Dynamic Autofocus Superior critical dimensions (CD) uniformity on warped or corrugated substrates Exposure Speed 300 x 300 mm2 in 5 minutes (write mode 3, two exposure modules) Full Facility Integration Customizable automatic loader, substrate chuck including warped substrates, custom workflow “wizards” and interface with manufacturing execution systems (MES) User-friendly SEMI-compliant user interface; customized workflow “wizards” for system operators

AVAILABLE MODULES

Raster Scan Exposure Mode Fast with excellent image quality and fidelity; write time is independent of structure size or pattern density. LED light source at 365 nm or 390 nm Vector Scan Exposure Mode Patterning continuous structures consisting of curved lines – where smooth contours are required. Laser light source at 405 nm and/or 375 nm Three Optical Setups Min. resolution of 0.6 µm, 1 µm and 3 µm; variable resolution within each mode Optional Overview Camera Fast and easy location of alignment marks or other features of interest on substrate Glovebox Integration Glovebox for patterning of sensitive materials in a controlled Nitrogen environment Draw Mode Import and overlay of BMP files on top of the real-time microscope image — as in a virtual mask aligner; simple lines and shapes can be drawn into the real-time camera image for immediate exposure Optical Autofocus Perfect exposure of small samples (<10 mm) Exposure Area Can be upgraded from 100 x 100 mm2 to 150 x 150 mm2 Choice of Exposure, Wavelength and Source Raster Scan Mode: LED light source at 365 nm or 390 nm. Vector Scan Mode: Laser light source at 405 nm and/or 375 nm

Exposure Wavelength

Diode laser sources at 375 nm and/or 405 nm can be mounted

together and used interchangeably to expose different photoresists

Exchangeable Chucks

Additional vacuum chucks for challenging samples like

small substrates, foils, or warped substrates

Customized vacuum chuck layout upon

request

Draw Mode

mport and overlay of BMP files on top of the real-time microscope

image – as in a virtual mask aligner; simple lines and shapes can be drawn into the

real-time camera image for immediate exposure

Autofocus

Air-gauge or optical autofocus for perfect exposure of small samples

(less than 10 mm)

Variable Substrate Sizes

From 3 mm to 6”; up to 8” upon request

Advanced Field Alignment

Automatic field-by-field alignment on individual dies

on the wafer for superior alignment accuracy

Automated Loading Module SEMI-standard BOLTS plane can be configured for open cassettes or Load Ports for FOUP. The number and configuration of ports can be selected and customized for round or rectangular substrates Manufacturing Execution System (MES) Patterning continuous structures consisting of curved lines – where smooth contours are required. Laser light source at 405 nm and/or 375 nm Backside Alignment Visual or through-wafer IR backside alignment available with 1 µm positioning accuracy Exposure Wavelengths High-power diode lasers with 7 W at 375 nm or 20 W at 405 nm with long lifetime are available Multipurpose Vacuum chuck Customized vacuum chucks are available for applications with special substrates (e.g. warped panels) Service Contracts Service contract grades for faster on-site support and participation in the spare parts pool

Reach Us

想要知道更多资讯吗? 没问题,快与我们联系!

© Stella International Corporation Limited