| |

|

|

| |

Ion Beam Milling (Etching) System 离子蚀刻系统 |

|

| |

As a micro fabrication method, Ion beam milling system is adopted to wide variety of applications such as RF devices, Sensors, Magnetic devices for R&D and mass production. Difficult-to-Etch materials (Au, Pt, Magnetic material, thin metal multi layers) can be easily processed by physical etching process (no reactive chemical). |

|

| |

|

|

Features of ion beam milling equipment |

|

| |

|

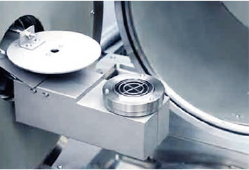

Planetary Stage |

| |

Planetary stage is employed in all type of systems for production. Thanks to planetary movement of stage and wafer holder, excellent milling uniformity is achieved.

|

| |

|

|

Direct Cooling or Indirect Cooling Stage |

| |

Direct cooling circulates cooling wafer inside wafer holder for excellent cooling performance. Indirect cooling enables the change of size and number of wafer holder easily.

|

| |

|

|

Dry Chuck |

| |

Wafer chuck with Dry Chuck Rubber incorporating metal powder ensures a good thermal conductivity and wafer attachment. Suitable rubber is available depending on the material of a sample.

|

| |

|

|

Design Freedom |

| |

We respond to customer's specific requirement as completely as possible in designing of system and offer custom-designed ion beam milling system.

|

| |

|

|

|

|

|

|

10IBE

For R&D.Small Chamber |

|

| |

|

|

|

| |

Features |

|

| |

Suitable for R&D. Small foot print |

|

| |

|

|

|

| |

|

4cm / 8cm / 10cm / 16cm Kaufman type ion source applicable |

|

| |

|

|

| |

|

Wafer size x number : Up to Φ8" x 1wfr |

|

| |

|

Sample that is other than the shape of wafer is mountable with adaptor |

|

| |

|

|

| |

|

End point detector (optional) for precise ending of etching

|

|

| |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

Φ2" single stage |

|

|

|

| |

|

|

|

|

|

|

|

20IBE-C

For R&D / Production.Medium Chamber

|

|

| |

|

|

|

| |

Features |

|

| |

Applied in a wide range from R&D to production |

|

| |

|

|

|

| |

|

20m Kaufman type ion source equipped |

|

| |

|

Wafer size x number : Φ3" x 8wfr, Φ4" x 6wfr etc... |

|

| |

|

Planetary movement achieves excellent milling uniformity |

|

| |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

Φ4" x 6wfr Planetary Stage |

|

| |

|

|

|

| |

|

|

|

|

|

|

|

20IBE-J

For Production.Large Chamber

|

|

| |

|

|

|

| |

Features |

|

| |

Having enough processing capacity in a batch |

|

| |

|

|

|

| |

|

20m Kaufman type ion source equipped |

|

| |

|

Wafer size x number : Φ4" x 12wfr, Φ5" x 10wfr, Φ6" x 8wfr etc... |

|

| |

|

|

| |

|

Planetary movement achieves excellent milling uniformity |

|

| |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

Φ4" x 12wfr Planetary Stage |

|

| |

|

|

|

| |

|

|

|

|

| |

|